EU 2020 agenda states that EU is the home to world leading manufacturing industries, game changing innovative technologies and an entrepreneurial infrastructure that can enable the transition to a resource efficient, sustainable, society. Unfortunately raw materials, crucial for these core industrial activities, are mostly imported from other countries.The challenge to increase the supply of materials from all types of sources requires a range of technologies, infrastructures, trade measures and policies that can dynamically adjust to different resource types, availability and product compositions.

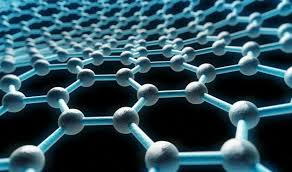

Luckily, in the last years researches in the field of nanostructured materials have taken many steps. Graphene is the most recent and most promising of carbon-based nanostructured materials. It is formed by a sheet of carbon atoms, one atom thick, arranged in a honeycomb lattice.

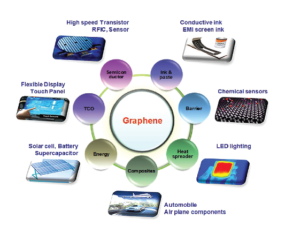

Thanks to its peculiar structure, graphene has many extraordinary properties: it is the strongest material ever tested, it conducts heat and electricity efficiently and it has high charge mobility, excellent mechanical properties and good chemical tunability.

In addition outside of its much vaunted manufacturing potential, graphene could be used within the aerospace industry to de-ice airs. In this case nanoplatelets of graphene can be mixed into a polymer resin; the  resin applied to the aircraft body

resin applied to the aircraft body

and its components form a tight jacket around it. An electrical current can then be passed through

this conductive jacket – either across the entire body of the aircraft or to specific components, such as the wings – providing heat, which would in turn melt the ice. This method provides no detrimental effect on aerodynamics and little weight, while the high conductivity of the resin also requires little electricity to be effective.Graphene was discovered in Europe, and several European groups are at the forefront of graphene research, among them the University of Manchester. Worldwide production is already on the tens of kilograms scale. Graphene-based products have been already commercialized by Austrian, Italian and Spanish companies. However, a strong activity on industrial production and application is ongoing in Asia and USA, who have the lead on

graphene-related patenting activities. To keep Europe at the center of this technologically relevant sector a strong international activity and a good network of infrastructures will be needed, relying on industrial involvement, top-level research and training of researchers on processing and application of graphene.

graphene-related patenting activities. To keep Europe at the center of this technologically relevant sector a strong international activity and a good network of infrastructures will be needed, relying on industrial involvement, top-level research and training of researchers on processing and application of graphene.

The Flagship Project GRAPHENE is collecting the most advanced European research about this topic bringing together academic and industrial researchers to take graphene from the realm of academic laboratories into European society in the space of 10 years, thus generating economic growth, new jobs and new opportunities.